Some background on Ferroelectric Materials

Ferroelectric materials possess high degrees of functionality, with highly exploitable electrical, mechanical and optical properties. As the most studied ferroelectrics are transition metal oxides with perovskite crystal structure their integration into heterostructure devices with other transition metal oxides with different but equally exciting properties (e.g., magnetism and superconductivity) is a direction that shows enormous potential for both exciting physics and breakthrough devices.

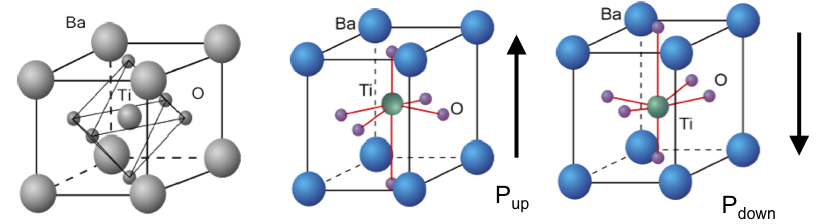

The materials we mostly work on in our lab are perovskite oxide ferroelectrics. These are materials which, in a particular non-centrosymmetric phase, have a spontaneous electrical polarization associated with an ionic displacement. In the case of BaTiO3 the dipole originates from the displacement of the Ti ion within the oxygen cage.

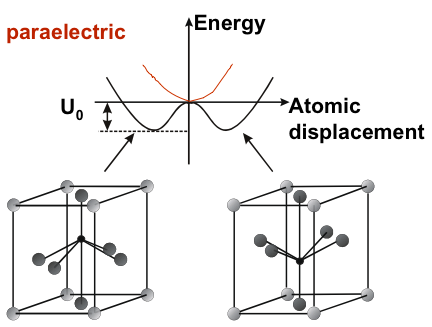

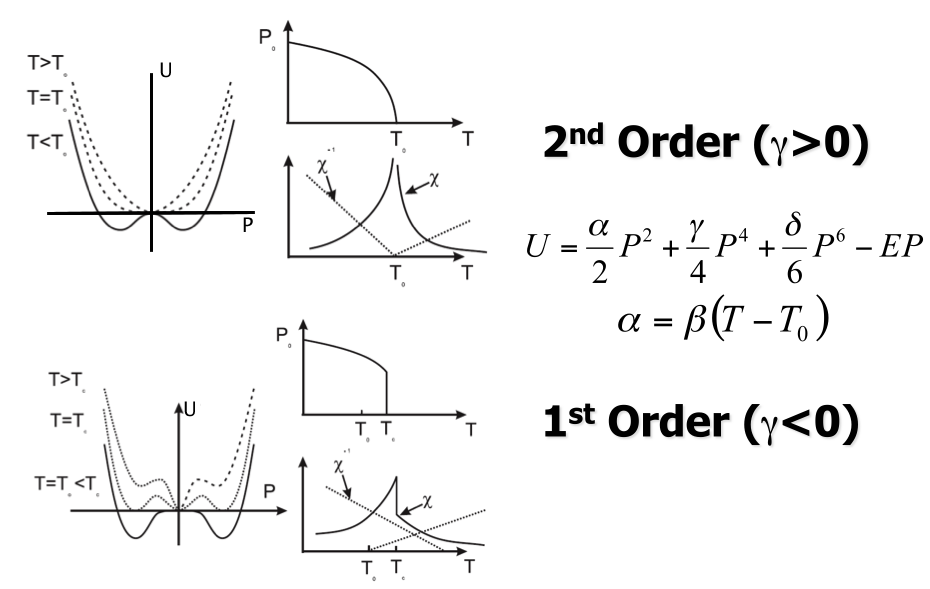

We can represent this situation with a diagram of energy (U) against polarization (P). This looks like a double well, ie. there are two equal energy minima for the system which have equal and opposite polarizations. In the ferroelectric phase either of these configurations are energetically more stable than a non-polar configuration where P = 0.

As the temperature of a ferroelectric material is raised the polarization usually decreases until at a particular temperature there is a phase transition to a higher symmetry phase. The figures show examples of transitions from a ferroelectric to a paraelectric phase (though there can also be transitions from one ferroelectric phase to another, as in BaTiO3). Because the interactions in ferroelectrics are long range ferroelectric phase transitions are usually well described by a mean field theory. The expression shown is a simple Landau expression for the free energy of a ferroelectric as a function of polarization. In this theory the P2 term has linear dependence on temperature. Depending on the sign of the P4 term the transition can be either continuous (second order) or discontinuous (first order). First order transitions may also exhibit temperature hysteresis.

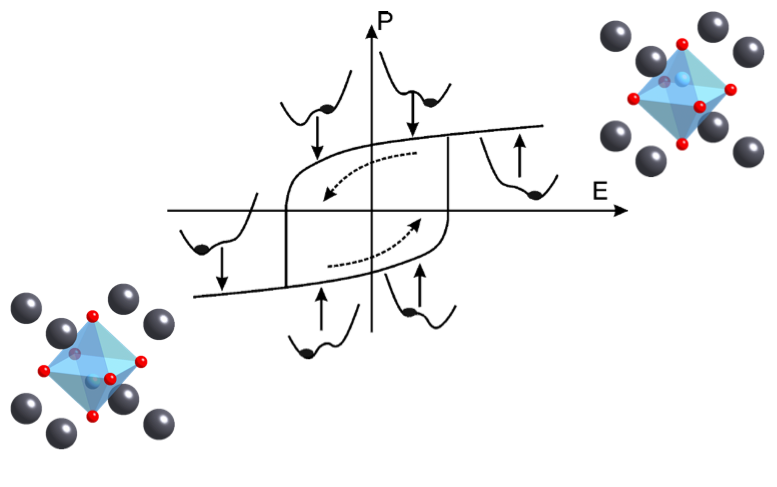

Application of an electric field causes one polarization state to be preferred over the over. In terms of our double well this is like pushing one well up and the other down. When applying a field in the opposite direction to the current polarization state of the sample switching only occurs once a particular value, known as the coercive field is exceeded. This characteristic leads to polarization hysteresis, ie. the systems response to a field depends on it’s history. An applied AC field will result in a polarization hysteresis loop as shown above.

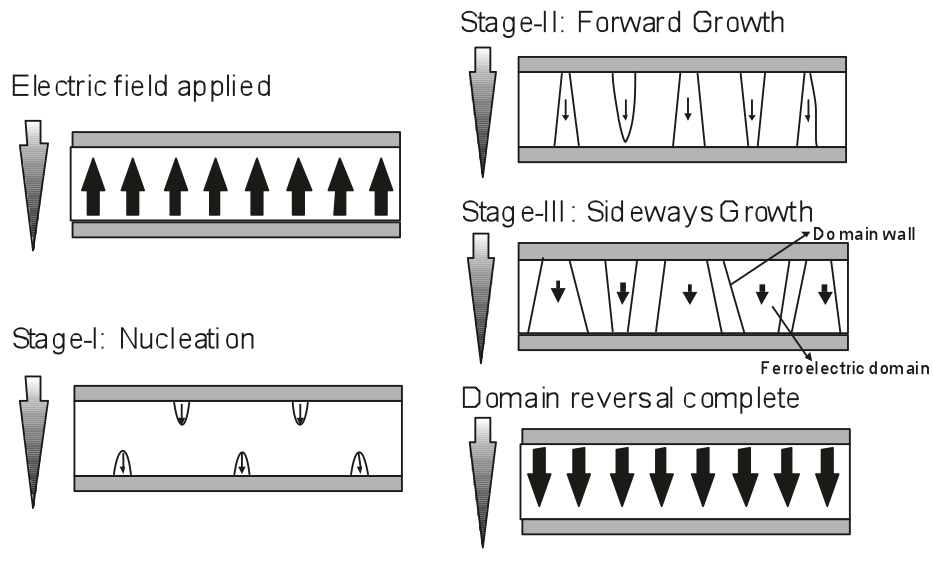

The previous picture might suggest that in a ferroelectric all the dipoles switch at the same time. However this does not usually happen. At applied fields much lower than the field that would be required for the whole crystal to switch at once a ferroelectric material will switch by a process of domain nucleation and growth. Nucleation usually occurs at particular locations in a sample where a particular polarization direction is favored over another and domains will nucleate at the same sites each time the sample switches (i.e. nucleation is inhomogeneous). The time scale for domain growth varies strongly on the strength of the applied field and the material and sample geometry, however it is usually seen that the forward growth of domains occurs first and is much faster than the subsequent sideways growth.

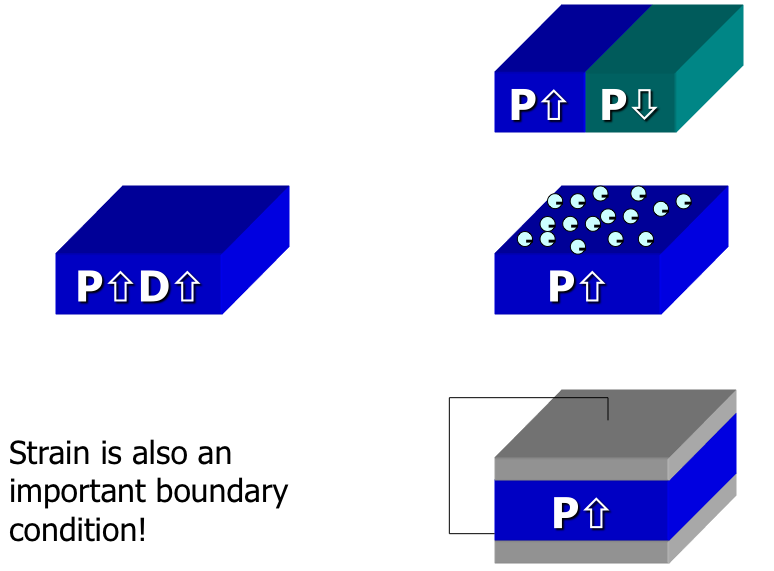

If we consider a uniformly poled ferroelectric slab with polarization P there is a uniform electric displacement D. Electric displacement can only change if there is free charge, so unless there is a electrode to provide screening charged ions will be attracted to the surface or the slab will develop a domain structure so that it does not have an overall electric displacement. It should be noted that the size and direction of the polarization is also highly dependent on the mechanical boundary conditions, or strain, applied to the slab.

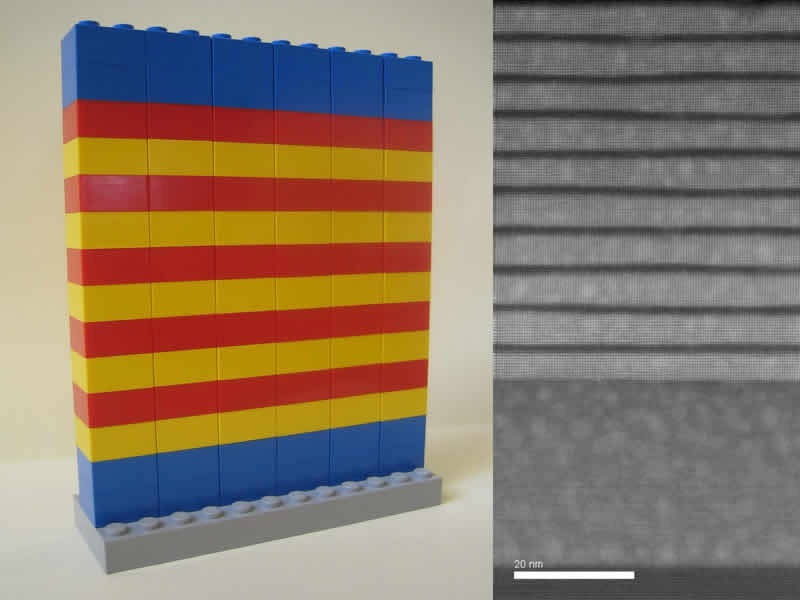

To build an artificial superlattice we deposit very thin layers of different materials on top of each other to build up a structure that can be thought of as a new material. For something to be a superlattice, as opposed to a multilayer, the periodicity should be small enough that it becomes the relevant periodicity of the new material. In the Lego model shown the grey base can be thought of as a substrate, the blue layers as electrodes and the yellow and red layers as two materials which form a superlattice.

The cross-sectional transmission electron microscopy image shown on the right is of a 10/3 PbTiO3/SrTiO3 superlattice grown on a SrRuO3 film (bottom electrode) on a SrTiO3 substrate. The superlattice was grown in our laboratory and the Transmission electron microscopy was performed at the CFN at BNL.

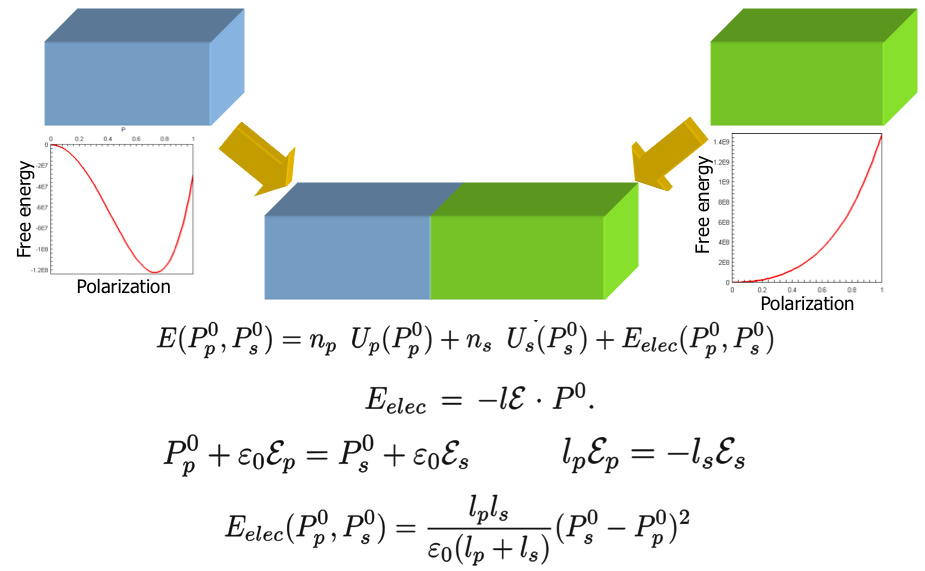

A key influence on polar properties in a multilayer structure is the electrostatic matching requirements between different layers. So long as a sample is prepared such that it does not have mobile charge, then the electric displacement must be constant from layer to layer. Discontinuities in polarization thus have to be compensated by electric fields, which cost free energy. The system can respond to this requirement to avoid polarization changes from layer to layer either by adopting a uniform polarization which best suits the sum of its components, or by evolving a domain structure.

Experimental Techniques

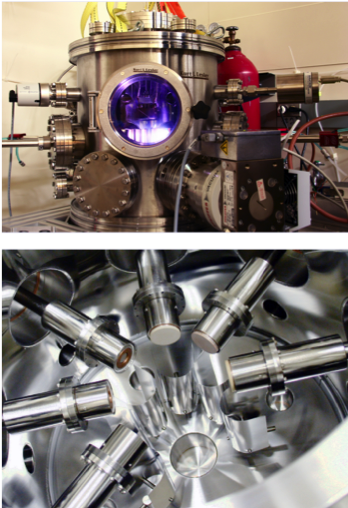

Precise control of interfaces in a multilayer requires advanced deposition techniques. The technique we primalu use is the off-axis RF magnetron sputtering technique. Our custom sputter deposition chambers can deposit multilayers composed of several materials without breaking vacuum. This allows the fabrication of high quality specimens containing both a number of complex interfaces, and also excellent electrical contacts in situ.

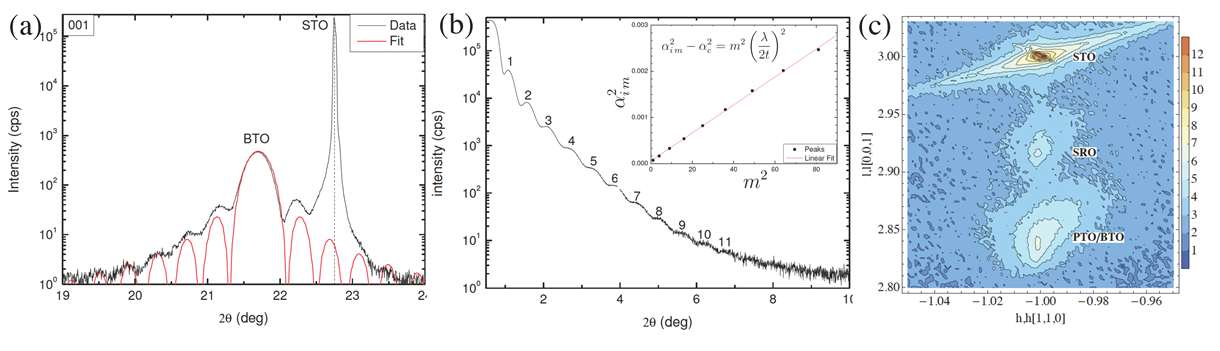

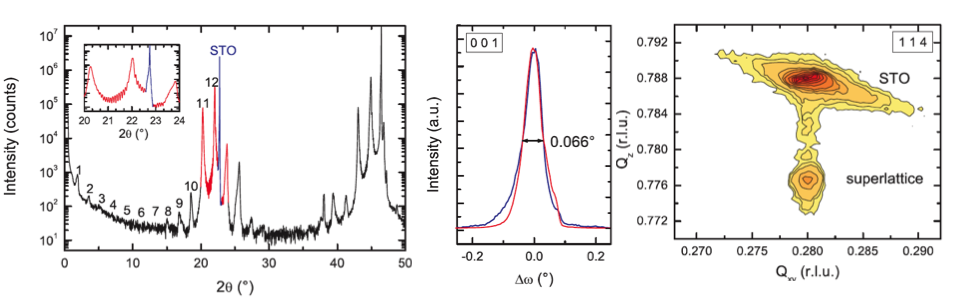

An X-ray diffractometer is an essential tool for the characterization of thin films. The growth rates for our deposition are very stable over long periods of time; this allows us to calibrate them using an X-ray diffractometer. Growth rates are extracted from fitting size effects in both diffraction (a) and reflectivity (b). We also use the x-ray diffractometer to measure the strain state of our films by performing reciprocal space maps ( c).

X-ray diffraction on superlattices can be used to obtain:

- Superlattice periodicity

- Total thickness of sample

- Quality of sample

- Degree to which coherency with substrate has been achieved

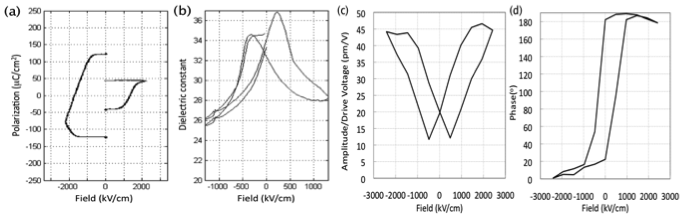

We have a home-built ferroelectric tester for polarization-field hysteresis measurements, giving flexibility in the method of execution our measurements. Quantities of interest that can be measured include polarization, coercive field, dielectric constant, dielectric loss, retention time (i.e., polarization stability), and fatigue and leakage properties. Further, our custom ferroelectric measurement system enables pulse based measurements that give more accurate information about the polarization, domain dynamics, and other electrical processes. The importance of pulsed measurement techniques is demonstrated in the figure. In one direction the samples have high leakage current, but in the other direction they do not. In this situation, we can extract the polarizations from the good half of the loop obtained from a unipolar pulse.

Measurements of the out-of-plane piezoelectric response to an electric field (d33) can be performed using an atomic force microscope, and are an important complement to the polarization and dielectric constant we measure with our electrical test equipment.